In industrial production, compressed air drying is a critical process. Industries such as precision manufacturing, food/pharmaceuticals, and electronics demand extremely stringent humidity control. Desiccant dryers are the ultimate solution, capable of reducing the dew point of compressed air to -40°C or lower. With their eco-friendly design, high efficiency, and operational reliability, these dryers have become the "all-round champions" of industrial drying.

The Five Core Components of Desiccant Dryers

1.Adsorption Towers: Dual-tower design enables alternating adsorption and regeneration cycles for uninterrupted operation.

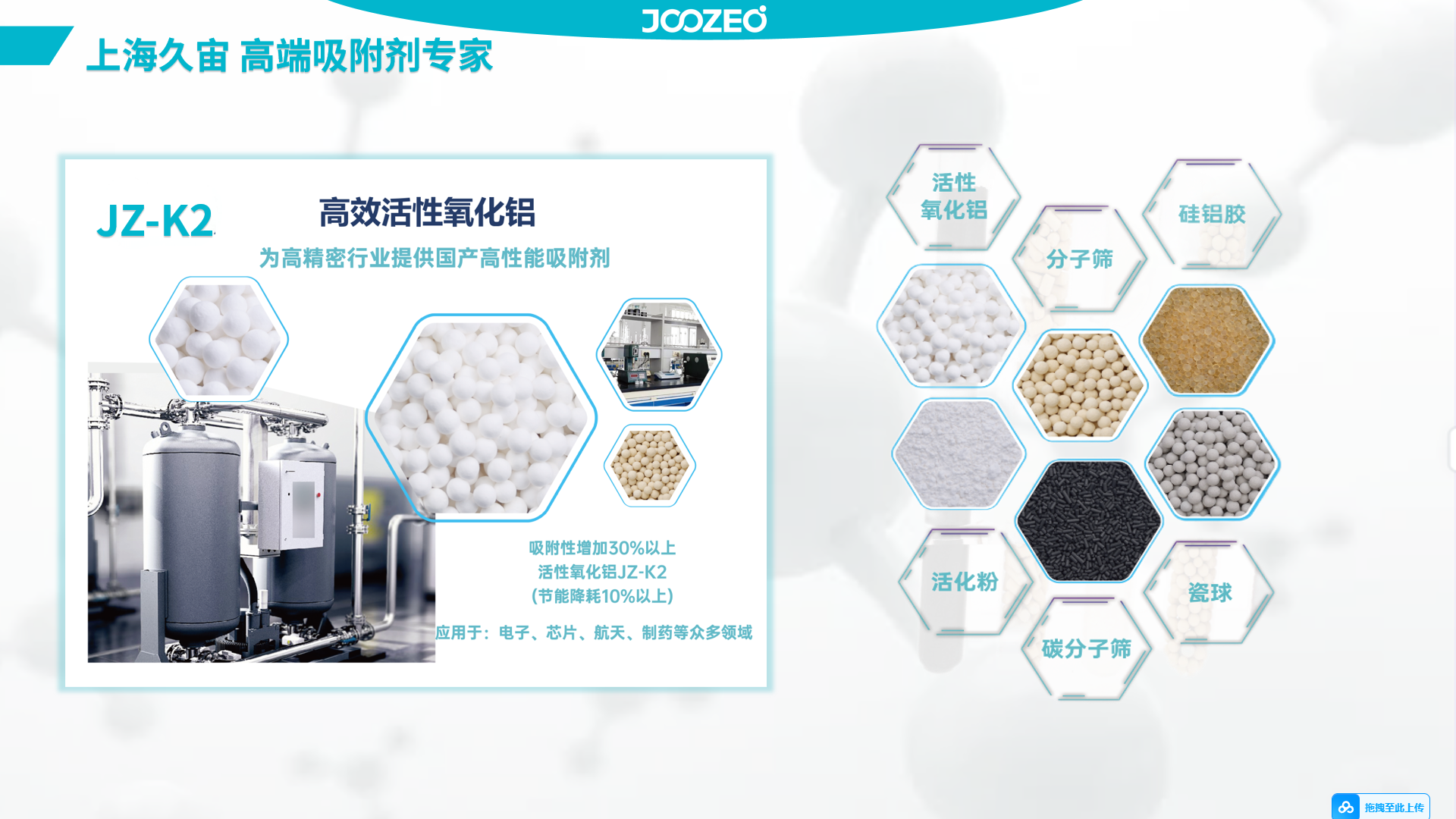

2.Adsorbents: High-performance materials like activated alumina and molecular sieves determine moisture removal efficiency and service life.

3.Switching Valves: Pneumatic or electric valves ensure precise gas flow control for seamless transitions between adsorption and regeneration.

4.Regeneration System: Includes a regeneration gas control valve and heater to regulate flow and temperature, ensuring efficient adsorbent recovery.

5.Control System: Intelligent programming allows parameter adjustments (e.g., adsorption/regeneration time) for optimized performance.

Workflow of Desiccant Dryers

1.Adsorption: Moist air enters the adsorption tower, where the adsorbent traps water molecules, releasing dry air.

2.Regeneration: Saturated adsorbents are regenerated via heating or purging to restore adsorption capacity.

3.Switching: Dual towers alternate tasks to maintain continuous drying.

As industrial technology advances, desiccant dryers continue to evolve. Innovations in adsorbent materials and smart control systems enhance energy efficiency, stability, and adaptability, meeting increasingly stringent industrial demands.

Post time: Feb-24-2025