Carbon molecular sieves, as highly efficient gas separation materials, have a development history dating back to the 1960s. Over more than half a century of technological evolution, these materials have expanded from their initial use in industrial gas separation to various key industries, forming a complete industrial chain.

In the early stages, carbon molecular sieves were mainly applied for separating industrial gases such as hydrogen, oxygen, and nitrogen. With advances in materials science and process innovations, their applications have continuously broadened. In the new energy sector, they are expected to play a greater role in fuel cell gas purification and energy storage system optimization; in environmental protection, they address complex exhaust gas treatment challenges; and in the pharmaceutical field, as drug purity standards rise, their applications will further deepen.

Moreover, through continuous material modification and process innovation, the performance of carbon molecular sieves will further improve, offering efficient solutions across a wide range of industrial sectors.

This development trend not only demonstrates the maturity of carbon molecular sieve technology but also highlights its crucial role in modern industrial systems. As application areas continue to expand, carbon molecular sieves will further support the green development of various industries.

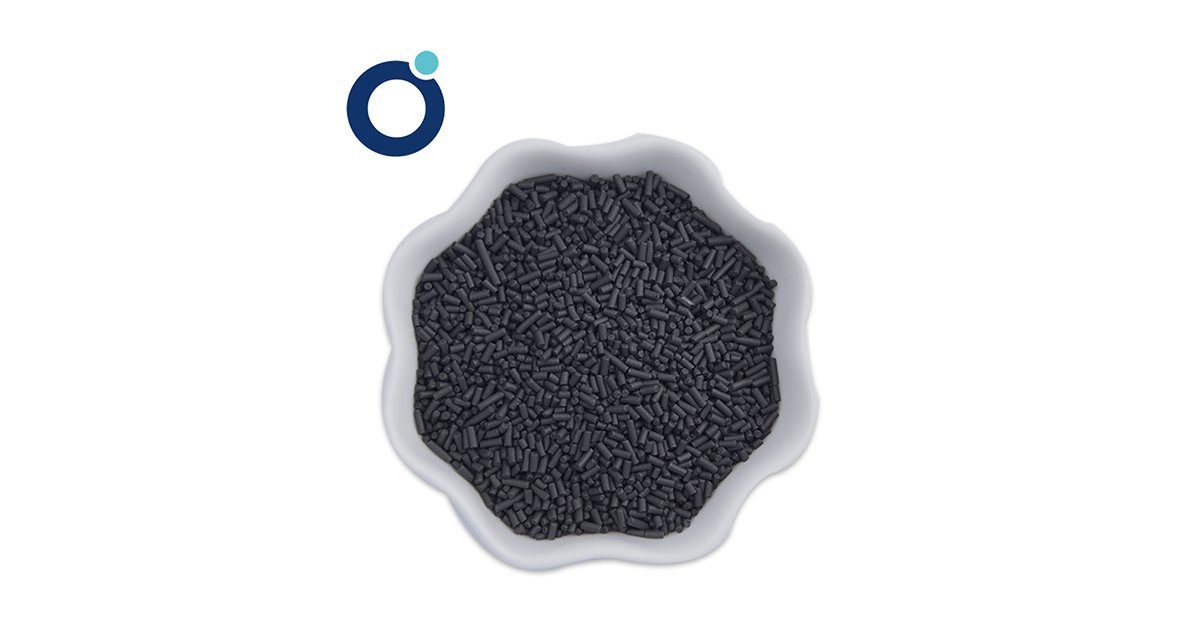

JOOZEO’s carbon molecular sieves are used in Pressure Swing Adsorption (PSA) systems to produce nitrogen with a purity of up to 99.999%. Based on customers’ nitrogen production rates, purity requirements, and equipment conditions, JOOZEO recommends the most cost-effective models.

Post time: Feb-11-2025