In the pneuamtic brake system, the compressed air is a working medium used to maintain a stable operating pressure and ensure air is clean enough for normal operation of the valve in system. The two elements of molecular sieve dryer and air pressure regulator are designed to provide clean and dry compressed air for the braking system and to keep the pressure of the system in a normal range (usually at 8~10bar).

In the car brake system, the air compressor output air containing impurities such as water vapor, if not treated, which may be converted into liquid water and combined with other impurities to cause corrosion, even freezing the trachea at extreme temperature, causing the valve lose efficacy.

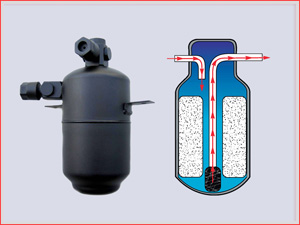

Automobile air dryer is used to remove water, oil drops and other impurities in the compressed air, it is installed after the air compressor, before the four-loop protection valve. And it is used for cooling, filtering and drying the compressed air, also it can remove the water vapor, oil, dust and other impurities, which provide dry and clean air for the braking system.

Automobile air dryer is a regenerative dryer with a molecular sieve as its desiccant. JZ-404B molecular sieve is a synthetic desiccant product with strong adsorption effect on water molecules. Its main component is a microporous structure of the alkali metal aluminum silicate compound with many uniform and neat holes and holes. Water molecules or other molecules are adsorbed to the inner surface through the hole, with the role of sieving the molecules. The molecular sieve has a large adsorption weight ratio and still holds water molecules well at high temperatures of 230 ℃.

The moisture in the system will corrode the pipeline and affect the braking effect, and it can even cause the failure of the braking system. Therefore, attention should be paid to the frequent discharge of water in the system and regular replacement of the molecular sieve dryer.